6 Common Mistakes to Avoid During Mini-Split Installations

Mini-split installations can seem straightforward, but there are common pitfalls that can affect efficiency, performance, and longevity. This article highlights the six frequent mistakes and how to avoid them for a successful installation. Mini-split systems, known for their flexibility and efficiency, are particularly suitable for homes without ductwork, which, according to the U.S Department of Energy, encompass approximately 12%-25% of residences. Avoiding common mistakes during mini-split installations is essential to capitalizing on the energy-saving and comfort-enhancing benefits these systems offer. By understanding and addressing these pitfalls, homeowners and installers can ensure reliable and optimal performance over the lifetime of the mini-split system. Proper planning, careful attention to manufacturer guidelines, and awareness of environmental and technical factors contribute to a smoother and more successful installation experience. Additionally, selecting the right installer and investing time in pre-installation preparation can prevent costly mistakes and reduce post-installation issues.

1. Ensuring Correct System Sizing

One of the most frequent mistakes during installations is selecting a system with the wrong capacity. The British Thermal Unit (BTU) rating is a crucial metric, indicating the system’s ability to heat or cool a given space effectively. A unit with too low a BTU rating may struggle to maintain comfort, while an oversized system can cycle on and off frequently, wasting energy and potentially causing wear. Proper sizing considers the room’s volume, insulation, window placement, and climate conditions. Professional load calculations provide a reliable method for determining the ideal system size, ensuring efficiency and optimal comfort. Homeowners should also factor in seasonal variations and potential future renovations that might affect room dimensions or thermal load.

Relying solely on online calculators can be risky, as they may not account for local variables or specific architectural features. Instead, combining preliminary tools with expert assessments offers the best approach. Proper system sizing also enhances indoor air quality, prevents unnecessary energy consumption, and prolongs equipment lifespan, making careful sizing a key step in any mini-split installation project. Considering system zoning for larger homes can also improve energy efficiency, allowing specific rooms to be cooled or heated individually according to usage patterns.

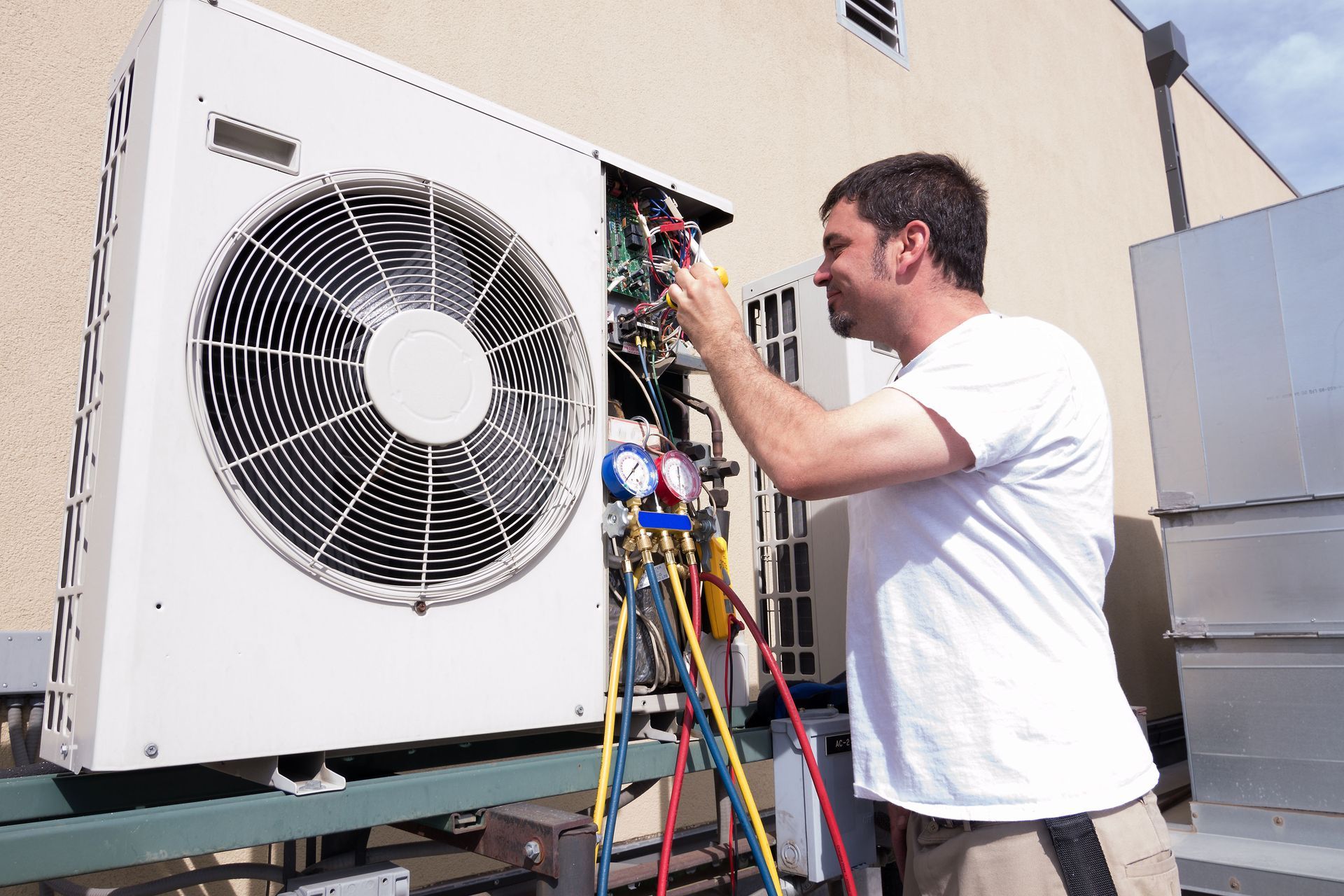

2. Optimizing Indoor and Outdoor Unit Placement

Proper placement of indoor and outdoor units is critical to system performance. Indoor units should avoid obstructions such as furniture, walls, or corners that limit airflow, while outdoor units require unobstructed spaces to dissipate heat effectively. Environmental factors, including sun exposure, wind, and moisture, must also be considered to protect components and maintain efficiency. Strategic placement reduces noise disturbances, improves airflow, and ensures the longevity of mini-split systems. Additionally, keeping outdoor units on raised platforms or shaded areas can prevent debris accumulation and reduce wear caused by exposure to the elements.

Accessibility for maintenance is another essential consideration. Units that are difficult to access can increase service costs and complicate routine upkeep. By evaluating structural stability, environmental exposure, and long-term accessibility, installers can prevent common placement issues and create a system setup that operates efficiently and quietly over time. Considering placement at the planning stage enhances system performance and user satisfaction. Proper placement also reduces the likelihood of pest intrusion or damage from nearby landscaping elements, contributing to long-term system reliability.

3. Ensuring Proper Refrigerant Line Installation

Refrigerant lines are vital to mini-split system functionality, and improper installation can significantly affect performance. Lines must be the correct length, properly insulated, and free from leaks. Oversized or undersized lines may compromise efficiency, while inadequate insulation can lead to energy loss and condensation issues, potentially causing mold or water damage. Regular inspections and the use of quality materials prevent leaks and maintain system integrity. Using flexible, pre-insulated lines can simplify installation while reducing the risk of kinks or damage during setup.

Leak testing post-installation is essential for confirming system airtightness. Techniques such as nitrogen pressure tests and soap bubble inspections detect even minor leaks that could otherwise reduce efficiency and necessitate costly repairs. Using professional-grade tools and materials ensures a robust installation that maintains refrigerant integrity over the life of the system. Correct refrigerant line installation is therefore a cornerstone of successful mini-split installations. Periodically inspecting refrigerant lines after installation can help detect issues early and maintain optimal system performance.

4. Addressing Electrical Considerations

Electrical mistakes are another common issue in mini-split installations. Mismatched voltage or amperage, improper grounding, and noncompliance with local codes can cause system malfunctions or pose safety hazards. Evaluating electrical requirements before installation ensures compatibility with the building’s infrastructure and avoids costly or dangerous errors. Circuit breakers must align with system specifications to prevent frequent tripping and protect the system from overloads. It’s also important to ensure wiring is protected from environmental factors like moisture or heat that could degrade insulation over time.

Conducting post-installation electrical safety tests verifies proper connections and system readiness. These tests evaluate voltage levels, wiring integrity, and system response under normal operating conditions. Professional oversight during installation minimizes risk, ensures compliance with regulations, and maintains both safety and efficiency. Proper attention to electrical factors is essential for reliable, long-term performance of mini-split installations. Homeowners should also consider surge protection devices to safeguard systems against voltage spikes and power irregularities.

5. Designing and Maintaining Drainage Systems

Drainage is often overlooked but is critical for preventing water damage and maintaining mini-split efficiency. Incorrect drain line installation can lead to leaks, mold growth, and system inefficiencies. Lines must have adequate slope, proper materials, and unobstructed flow paths. Condensate pumps may be necessary in certain scenarios to ensure smooth water removal. Regular maintenance and cleaning of drainage lines and pans prevent blockages and prolong system life. Proper drainage design also prevents stagnant water accumulation that could attract pests or cause structural damage.

Routine inspections and the use of preventative measures, such as anti-algae treatments, safeguard against unexpected blockages and potential damage. By addressing drainage design during mini-split installations, homeowners can protect their investment and ensure reliable system performance. Efficient drainage design also enhances indoor air quality and prevents potential health hazards associated with moisture accumulation. Planning for future maintenance and providing clear access points for servicing can further prevent costly problems down the line.

6. Following Manufacturer’s Guidelines and Best Practices

Adherence to manufacturer instructions is crucial for successful mini-split installations. Ignoring these guidelines can reduce efficiency, void warranties, and compromise system safety. Documentation provides step-by-step instructions, recommended materials, and detailed specifications. Engaging professional installers familiar with these requirements ensures compliance and mitigates the risk of mistakes. Even skilled DIYers should seek professional guidance for complex systems to ensure long-term success. Reviewing installation manuals in advance and maintaining organized documentation can prevent misunderstandings during setup.

Installer training and certifications enhance understanding of best practices, safety standards, and emerging technologies. Following guidelines and maintaining ongoing education ensures systems are installed correctly, function efficiently, and deliver maximum comfort. Deviating from manufacturer recommendations can lead to operational failures, increased maintenance needs, and reduced energy savings. Proper adherence safeguards both the homeowner’s investment and system longevity. Additional benefits include improved warranty coverage, faster troubleshooting, and a smoother overall installation process.

Successful installations require careful attention to sizing, placement, electrical setup, refrigerant lines, drainage, and adherence to manufacturer instructions. By avoiding common mistakes and following best practices, installers can maximize system efficiency, longevity, and user comfort. Understanding the technical and environmental factors affecting mini-split systems ensures consistent performance and energy savings. For professional, reliable, and efficient mini-split installations that adhere to industry standards, contact Navarro's Heating & Air Conditioning Inc to schedule your service and enjoy optimal comfort in your home.

Share On: